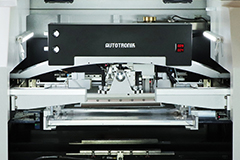

AP435 AUTOMATIC SMT STENCIL PRINTER

![[field:title/]](/images/AP435.jpg)

FEATURES

- Precise height adjustment of PCB holding table using ball-screw driven control.

- Accurate vertical adjustments of stencil frame driven by ball-screw in fast and quiet movements.

- Automatic stencil cleaning device included for ease of use and continuous production.

- Advanced imaging system allows wide selection of fudicial mark patterns on stencil. No specialized fudicial mark on stencil is required. Alignment of stencil on PCB board can easily be achieved for the best printing result.

- With simultaneous control of all axis movements, machine can quickly restore to home position for quick restart of next printing task.

- Machine parameter set up is easy so that changeover between different production lines is simple and fast. Multiple light source selection feature helps easy handling of different colored PCB when learning fudicial reference points.

- Multiple user permission levels available, avoid important machine parameters to be accidentally changed due to human error.

FEATURES

PCB / Stencil positioning system

PCB / Stencil positioning system  Underside stencil cleaning system w/. sprinkler

Underside stencil cleaning system w/. sprinkler  Solid case iron base lifting structure

Solid case iron base lifting structure  Temperature, humidity & pressure monitoring

Temperature, humidity & pressure monitoring

DETAILS

Iron casting BaseIron casing base to make the platform lifting structure more stable, and affordable the impact force when the conveyor platform rises and falls at higher speed, then make the platform movement precisely and faster than help for the productivity increase.

Iron casting BaseIron casing base to make the platform lifting structure more stable, and affordable the impact force when the conveyor platform rises and falls at higher speed, then make the platform movement precisely and faster than help for the productivity increase.  Temperature & Humidity Sensor, Squeegees Pressure MeterEnvironmental monitoring system can avoid the accelerated oxidation of solder paste due to the temperature and humidity out of set range.

Temperature & Humidity Sensor, Squeegees Pressure MeterEnvironmental monitoring system can avoid the accelerated oxidation of solder paste due to the temperature and humidity out of set range.

Squeegees’ printing pressure is real-time monitoring & alarm system.

Positioning SystemPositioning camera system to teaching and recognize the marks of PCB and stencil by up & down camera viewing function£¬to ensure the stable repeatability accuracy within ± 0.01mm.

Positioning SystemPositioning camera system to teaching and recognize the marks of PCB and stencil by up & down camera viewing function£¬to ensure the stable repeatability accuracy within ± 0.01mm.  Cleaning SystemStencil cleaning system move back and forth to clean the whole stencil, effectively shorten the width of the whole production line.

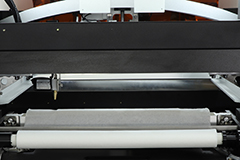

Cleaning SystemStencil cleaning system move back and forth to clean the whole stencil, effectively shorten the width of the whole production line.  Solder Paste Supplemental (Option)Auto solder paste supplemental system helping to refill the solder paste automatically and manpower save.

Solder Paste Supplemental (Option)Auto solder paste supplemental system helping to refill the solder paste automatically and manpower save.  Glue Dispensing System (Option)Glue dispensing system is optional for PCBA process requirement of solder paste printing and glue dispensing combination.

Glue Dispensing System (Option)Glue dispensing system is optional for PCBA process requirement of solder paste printing and glue dispensing combination.

SPECIFICATION

| PCB Size: | 50 x 50 mm ~ 300 x 340 mm mm (Option: 400 x 340mm) |

| Stencil Size: | 400 x 370 mm ~ 737 x 737 mm |

| PCB Thickness: | 0.4 - 6 mm |

| PCB Warpage: | < 1% of PCB diagonal line |

| Repeatability: | ±0.01 mm |

| Printing Accuracy: | ±0.025 mm |

| Print Speed: | 6mm/s ~ 200mm/s |

| Printing cycle time: | 7s (exclude transporting & cleaning) |

| Transport Height: | 900 ± 40 mm |

| Transport Direction: | Left-Right / Right-Left / Left-Left / Right-Right |

| Transport Speed: | max. 1500mm/s |

| Transport way: | One stage |

| PCB Fixation: | Side clamp, magnetic support pins, vacuum toolings |

| Support System: | Conveyor stage and vacuum |

| Interface: | SMEMA Interface |

| Squeegee Type: | Metal (std.) / Plastic squeegee (45 / 55/ 60 degree) |

| Squeegee Pressure: | 0 ~ 8 kg (motorized control) |

| Print Mode: | Single or double side printing |

| Cleaning System | Vacuum Sucking£¬Dry / Wet / Vacuum |

| Camera / FOV: | CCD / FOV 7 x 9 mm |

| Fiducial Type: | Circular / Square / Trianglar / Rhombus / Polygon etc |

| Fiducial Size: | 0.5 to 3 mm |

| X, Y, R adjustment: | X ± 7 mm, Y ± 5 mm, R ± 2 degree |

| Environment monitoring: | Temperature & humidity real-time monitoring |

| Operation System: | Windows 10 |

| Air pressure: | 4.5 ~ 6 kgf / cm2 |

| Power: | 220V±10% 50-60hz 3kW |

| Dimension: | L 1220 x W 1375 x H 1500 mm |

| Weight: | approx. 890kg |

* We reserve the right to make changes without notice.